Our

company

Alpenfrucht – A family company that knows what the sector needs

The engineer Rudolf Bertolini is the General Manager and main shareholder of Alpenfrucht. He obtained thorough training and education in all fields of beverage technology at the former engineering school for Viniculture, Horticulture, and Beverage Technology in Geisenheim, Rheingau. After successfully earning his degree in Engineering, Mr. Bertolini broadened his skills first as director of the laboratory and then as head of operations in large Italian fruit-processing companies.

Alpenfrucht - the big semi-finished fruit producer

As General Manager of one of the leading producers of semi-finished fruit products in Italy, his daily goal was and remains the satisfaction of customer demands – a sometimes challenging task.

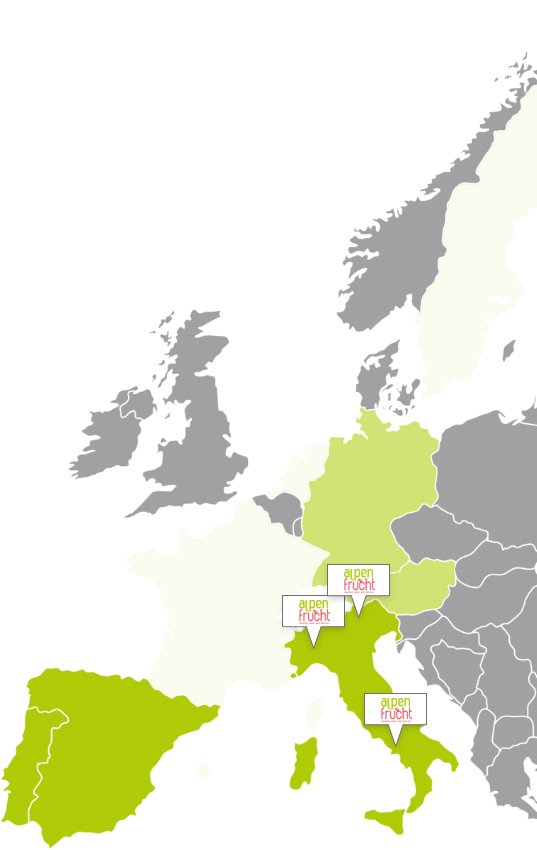

In order to meet customer wishes more efficiently and quickly, in 1995, Bertolini GmbH (Ltd.) was founded. Its purpose was to purchase and process industrial fruits and to process them into fruit juice, juice concentrate, and fruit pulp. The processing plants of the Alpenfrucht company (which was founded to process and store fruit products for Bertolini GmbH) are situated in the main fruit-growing regions of Italy: in Tarantasca (Cuneo, Piemont) – a main area of cultivation for apples, pears, and peaches – as well as in Giugliano (Naples-Campania), which is renowned throughout Europe for its apricots and peaches.

Within just a few hours of harvesting, the sun-ripened fruits are delivered to the processing plants, where they are checked and processed. The many hours of sunshine during the growing season and the rapid processing form the basis for the high quality of the resultant fruit products. The gentle treatment in machines capable of quickly processing even large quantities preserves the fruit’s natural quality. In order to quickly and reliably deliver the goods to customers and maintain a high level of quality, large storage capacities are necessary.

Our

production

The processing plants operated by Alpenfrucht can stock 30 million liters under aseptic (germ-free) conditions, and 6 million kg of fruit juice concentrate. These stocks are used to make the desired mixtures for the juice producers in Germany, France, Netherland, Austria, and the rest of Europe. The standardization of the mixtures, their trackability, and the food safety are made possible largely by the strict quality management and the use of the company’s own labs in all facilities.

Today, constant improvement in all areas and the rapid and reliable fulfillment of customer needs are the cornerstones of the company’s continued success.

The manufacture of fruit pulp

Fruit pulp is the puréed flesh of the fruit. The fruits are chopped and the fruit pits, seeds, and other non-edible parts removed. The product is then blanched, passed, degassed, and finally pasteurized and stored in aseptic tanks having a capacity of 30 – 100 tons. The latest fruit processing lines can process 40 tons per hour of fruit. Modern passing equipment guarantee a high throughput of uniform, appealing, highly viscous fruit pulp without visible residual seeds or skin (which could result in brown dots in the purée).

Fruit pulp can be manufactured in various different degrees of fineness, e.g., pears can be reduced down to 0.4 mm for nectar in Tetra packages or to 0.5-0.6 mm for filling in bottles. A new degassing and pasteurization technique minimizes the thermal stress; the fruity freshness is preserved. We will deliver to you the kind of fruit pulp best suited to your requirements.

The manufacture of fruit juices and concentrates

The scrubbed, sorted fruits (apples, peaches, pears, kiwis, etc.) are chopped up and, if needed, treated with enzymes for better dejuicing. They are then gently dejuiced using pneumatic cylinder presses. In order to prevent enzymatic discoloration, the resultant juice is degassed and pasteurized. Depending upon the customer’s wishes, in the case of naturally turbid juices, we adjust the level of turbidity.

The resultant naturally turbid liquid is converted to naked juice by means of the enzymatic decomposition of pectin and starch and the subsequent extraction of the turbid components using gelatin and bentonite or by means of ultrafiltration. Naked juice can be employed as direct juice for high-quality beverages or as juice concentrate (with a Brix of 65-70) for various different purposes. In the case of Alpenfrucht, the juice is concentrated gently, in a multi-stage plant.

The fruit concentrate can also be refrigerated and stored for special purposes. The visual and sensory characteristics of the freshly-made fruit juice concentrates are thus preserved for a long time.

Technique

The sun-ripened, hand-picked fruits are delivered to the individual plants in large crates. Before acceptance, the fruits are subjected to a strict quality control process – still the most important factor for quality – including a determination of such physico-chemical parameters such as the Brix (sugar content), pH value, and acidity. All of the documentation (field book) is likewise checked.

Only after successfully passing this check are the trucks unloaded and – depending upon their degree of ripeness – either immediately processed or allowed to continue ripening for a few hours to days.

All of the fruits are scrubbed several times prior to processing and then manually sorted. Finally, they are rinsed with drinking-water quality water.

Quality

The quality of a fruit product is dependent primarily upon the quality of the fruit and their rapid processing:

Alpenfrucht has reliable suppliers in the big Italian fruit-producing areas who can deliver their goods to the nearest processing plant (Tarantasca/CN, Napoli, and Policoro/Matera) in the shortest time. The planning and standardization of the fruit products is another important quality factor. This is the task of the laboratory – each plant has its own lab – and of the Quality Management team.

In the labs, the Brix content (percentage by weight of sugar per 100 grams of product), the pH value, the total titratable acidity, NTU (a measure of turbidity), the viscosity (Bostwick), and last but not least the microbiology (yeasts, mildew, total germ number) as well as sensory parameters are routinely analyzed.

According to the test plan, residues of plant protectants, patulin, heavy metals, and other contaminants are regularly checked by accredited laboratories.

Gemäß Prüfplan werden noch Pflanzenschutzmittelrückstände, Patulin, Schwermetalle und andere Kontaminanten von akkreditierten Labors regelmäßig geprüft.

Quality criteria that are important for the customer are of decisive importance to us, too.

TARANTASCA

- SGF Certificate Tarantasca

- FSSC 22000 Certificate Tarantasca

- BIO Certificate Tarantasca

- HACCP Certificate Tarantasca

- ISO 14001 Certificate Tarantasca

- ISO 22000 Certificate Tarantasca

- ISO 22005 Certificate Tarantasca

- KOSHER Certificate Tarantasca

- KOSHER New Products Certificate Tarantasca

- Politica Ambientale

- Sicurezza Alimentare

GIULIANO

Our

factories

The Giugliano factory (NA)

The Giugliano plant is located in Naples